Check if the lubricating oil is sufficient whether the air pressure of the air pump is at a normal value and whether the components such as the motor are overheated.

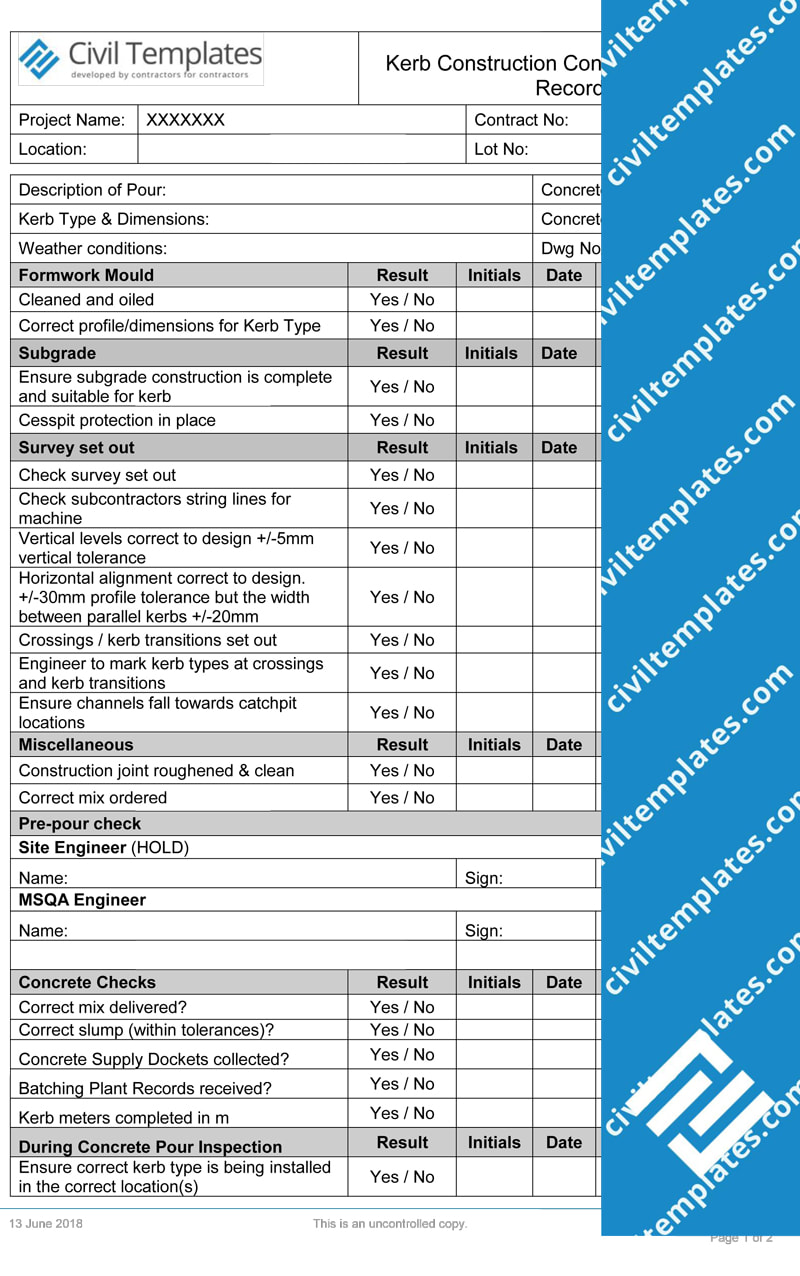

Concrete batch plant inspection checklist.

The producer s staff should work with the.

Whether spare parts and accessory equipment are complete.

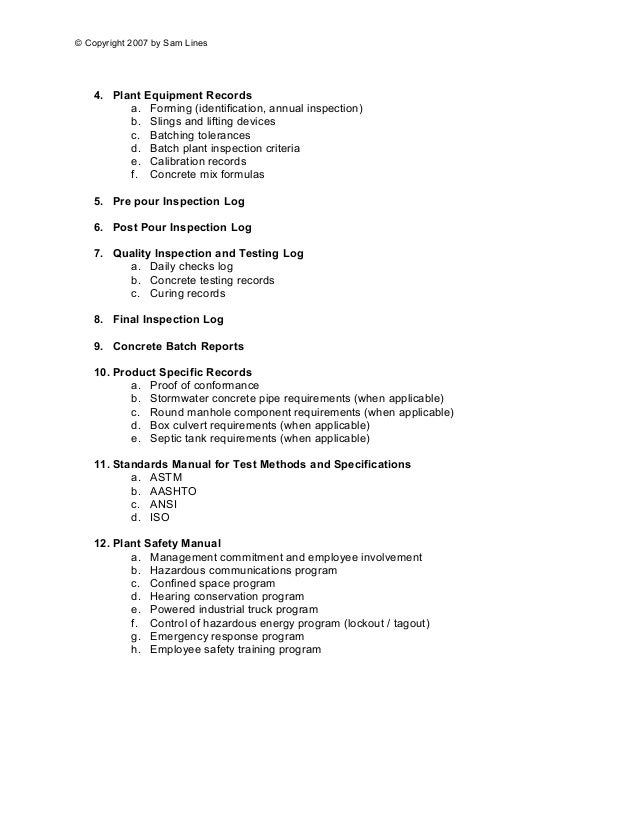

A 5 winter concrete 1 batching equipment 2 b 1 scales 2 b 2 batchers general 3 b 3 accuracy of plant batching 4.

Here is the concrete batch plant inspection checklist.

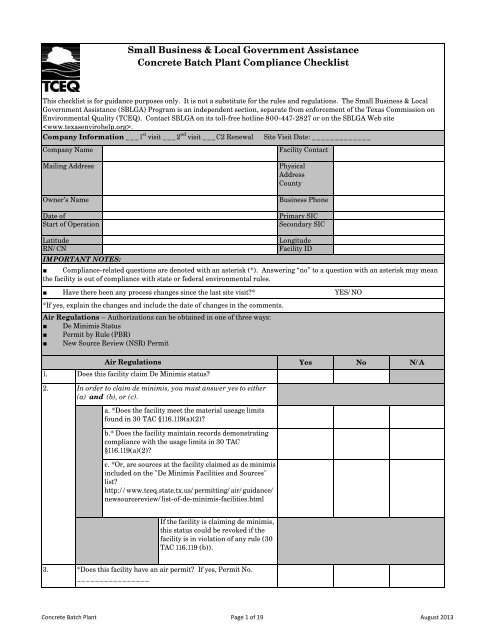

Annual ins1 ins2 complaint discovery ci re inspection fui arms complaint no.

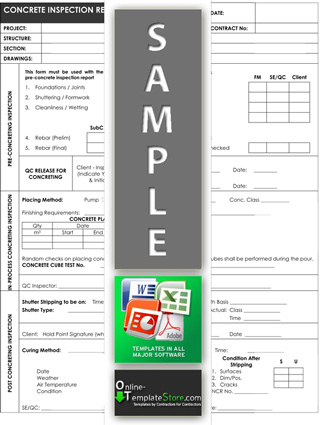

Perform the plant inspection quickly and accurately.

Concrete batching plant compliance inspection checklist inspection type.

3 00 pm facility name.

Push the rolling parts of the concrete batch plants by hand to check whether the rolling is active whether there is any stuck and whether there is looseness between the parts.

2 the mixing system.

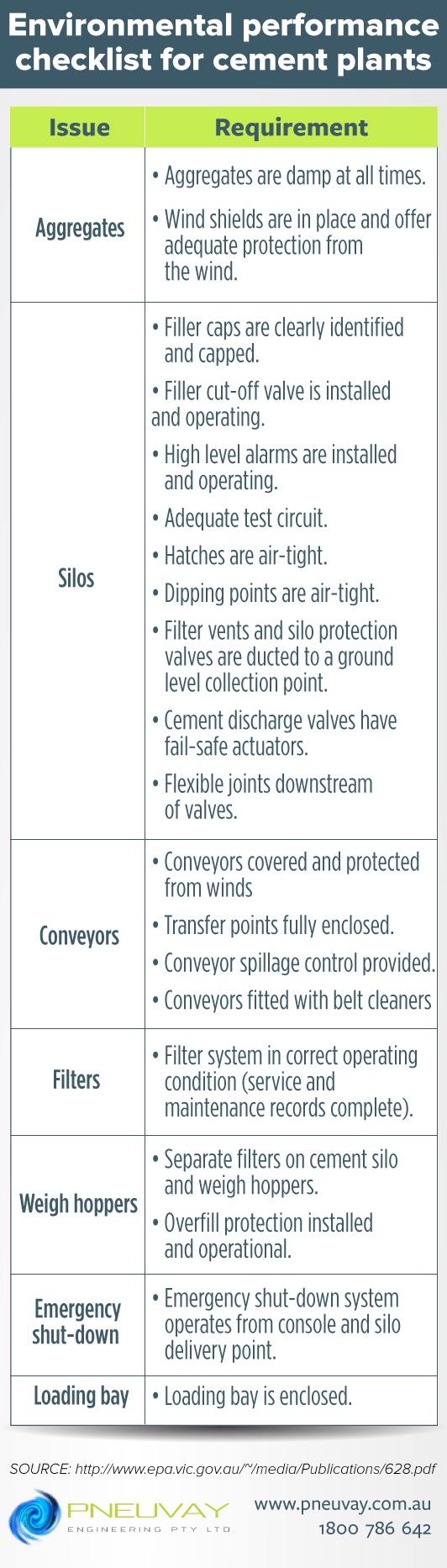

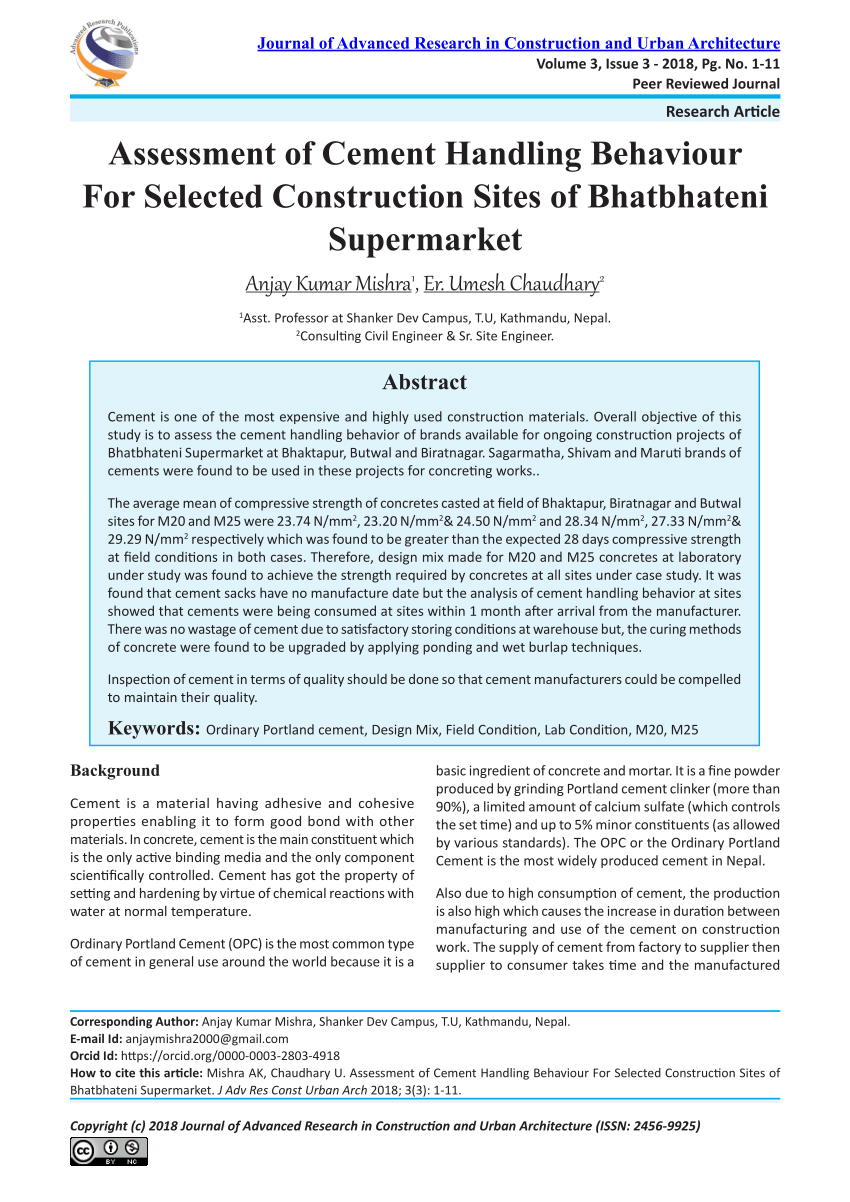

Material storage and handling the inspection will cover cement aggregate water and admixture storage.

Checklist for ready mixed concrete production facilities 2.

The ticketing system is checked to ensure the proper information appears.

Batching equipment scales weigh batchers volumetric batching devices for water dispensers for liquid admixtures accuracy of plant batching batching systems and recorders are all inspected.

Whether the machine is clean no oil no serious corrosion.

Central mixing operations and shrink mixing operations are examined.

1 the machine whether the main work performance achieve the rated level.

Some important highlights of the checklist include.

Clean the remaining materials in the plant in time to ensure the internal and surrounding environment of the mixing station is clean.

Whether metal structure is with no deformation no artifacts desoldering.

8989 ulmerton road largo fl responsible official.

.jpg)